Sodium Fast Reactor (SFR)

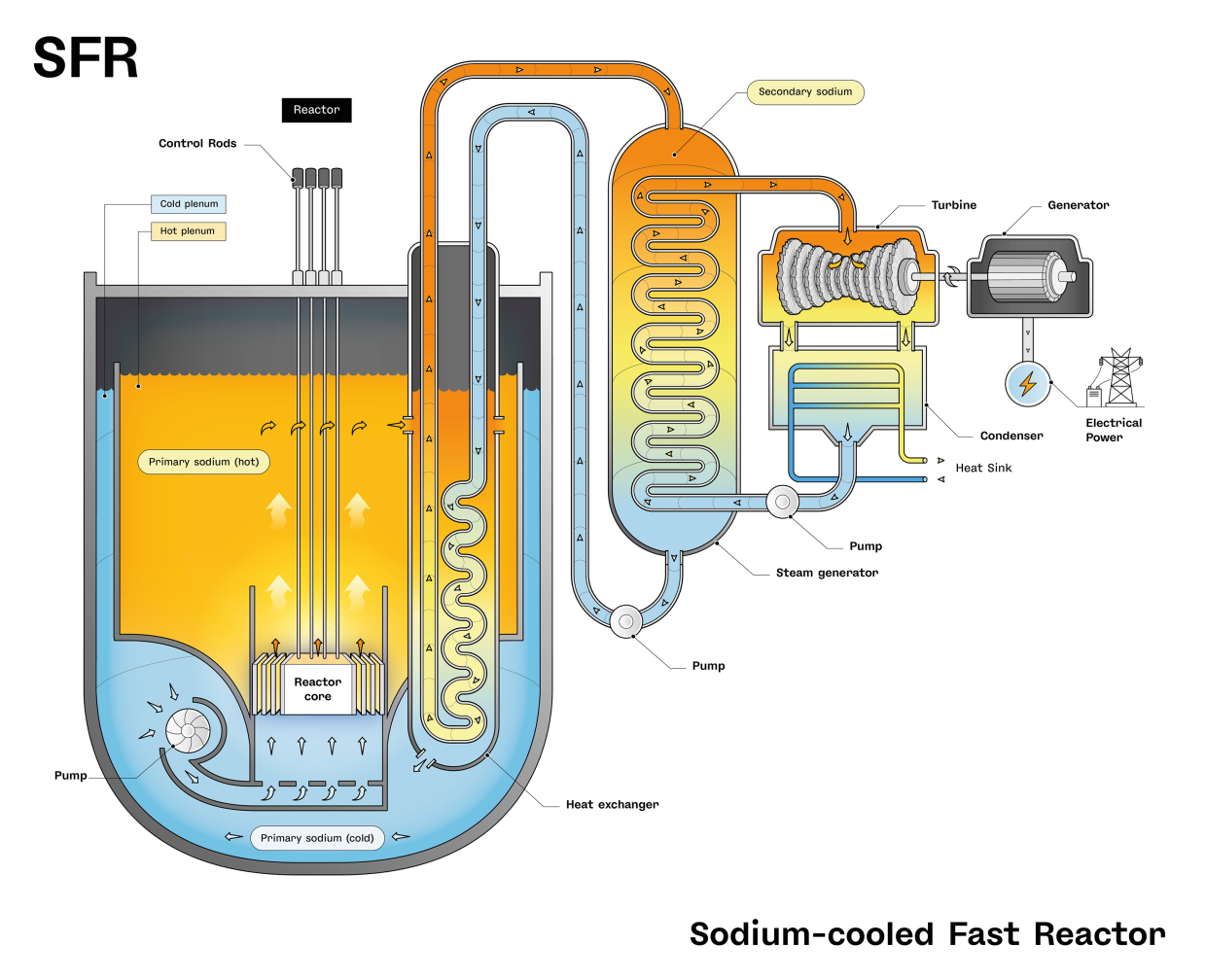

The Sodium-cooled Fast Reactor (SFR) utilizes liquid sodium as a coolant and functions within the fast neutron spectrum, which facilitates a high power density and the advantage of low-pressure operation. Despite ongoing challenges in its development, SFRs draw on the collective experience of over 20 reactors globally, amounting to more than 400 reactor-years of operation. This extensive experience has progressively improved the safety and reliability of these reactors. Among Generation IV systems, the SFR boasts the highest number of constructed reactors and the most comprehensive operational history. Employing Uranium-Plutonium Mixed Oxide Fuel (MOX), SFRs present the possibility of closing the fuel cycle and burning transuranic actinides, thereby enhancing fuel usage efficiency and diminishing radioactive waste. Certain designs achieve breeding ratios greater than one, which promotes the sustainability of the reactor concept. With operational temperatures ranging between 500-550°C, SFRs has a greater thermal efficiency than current Light Water Reactors (LWRs) .

Presentation of the Sodium Fast Reactor System

The SFR is an attractive energy source for nations that desire to make the best use of limited nuclear fuel resources and manage nuclear waste by closing the fuel cycle.

As well as the advantages mentioned above, the SFR has additional several advantages such as:

1) flexibility of their operating modes (“transmuter”, “converter” and “breeder”),

2) compact core designs due to their high-power density,

3) natural circulation designs which can remove decay heat from the core without relying on dynamic equipment such as pumps, especially in case of a station blackout event,

4) oxygen-free environment which prevents corrosion.

Although important parts of these aspects have already been explored and improved through SFR reactors that have been operating for a long time, the SFR has several challenges such as

1) technology establishment of handling sodium which are chemically reactive with air and water and not transparent,

2) further development of passive safety approaches,

3) development of high-performance fuels and their recycle technologies,

4) improvement of unit cost of power generation.

Under the GIF, the international SFR R&D projects named “Advanced Fuel (AF)“, “System Integration and Assessment (SIA)“, Component Design and Balance-of-plant (CD&BOP)“, and Safety & Operation (SO) have been arranged and conducted to effectively meet GenIV system goals.

Attributes of the SFR

The SFR is an attractive energy source for nations that desire to make the best use of limited nuclear fuel resources and manage nuclear waste by closing the fuel cycle. The SFR closed fuel cycle enables regeneration of fissile fuel and facilitates management of minor actinides. However, this requires that recycled fuels be developed and qualified for use. The main characteristics of the SFR for actinide management mission are:

- Consumption of transuranics in a closed fuel cycle, thus reducing the radiotoxicity and heat load which facilitates waste disposal and geologic isolation, and

- Enhanced utilization of uranium resources through efficient management of fissile materials and multi-recycle.

The SFR operates with high energy neutrons that are more effective at fissioning actinides and breeding fissile materials. For this purpose, the SFR uses liquid sodium hardly moderating neutrons as the reactor coolant, allowing high power density with low coolant volume fraction and operation at low pressure. While the oxygen-free environment prevents corrosion, sodium reacts chemically with air and water and requires a sealed coolant system.

Important safety features of the Generation IV system include a long thermal response time, a reasonable margin to coolant boiling, a primary system that operates near atmospheric pressure, and an intermediate sodium system between the radioactive sodium in the primary system and the power conversion system. Water/steam, supercritical carbon-dioxide or nitrogen can be considered as working fluids for the power conversion system to achieve high performance in terms of thermal efficiency, safety and reliability. With innovations to reduce capital cost, the SFR is aimed to be economically competitive in future electricity markets. High level of safety achieved through inherent and passive means also allows accommodation of transients and bounding events with significant safety margins.

Much of the basic technology for the SFR has been established in former fast reactor programmes, and were confirmed by the Phenix end-of-life tests in France, the restart of Monju in Japan and the lifetime extension of BN-600 in Russia. New programs involving SFR technology include the Chinese experimental fast reactor (CEFR) which was connected to the grid in July 2011, BN-800 In Russia started operation in 2016, and India's prototype fast breeder reactor (PFBR) which began its fuel loading in 2024. The SFR is considered to be the nearest-term deployable system for actinide management.

Plant size options under consideration range from small, 50 to 300 MWe, modular reactors to larger plants up to 1 500 MWe. The outlet temperature is 500-550°C for the options, which allows the use of the materials developed and proven in prior fast reactor programs. The reactor unit can be arranged in a pool layout or a compact loop layout. Three options are considered:

- A large size (600 to 1 500 MWe) loop-type reactor with mixed uranium-plutonium oxide fuel and potentially minor actinides, supported by a fuel cycle based upon advanced aqueous processing at a central location serving a number of reactors.

- An intermediate-to-large size (300 to 1 500 MWe) pool-type reactor with oxide or metal fuel.

- A small size (50 to 150 MWe) modular-type reactor with uranium-plutonium-minor-actinide-zirconium metal alloy fuel, supported by a fuel cycle based on pyrometallurgical processing in facilities integrated with the reactor.

| SFR Reactor Parameters | Reference Value |

|---|---|

| Spectrum | Fast (>1MeV) |

| Core Outlet Temperature range | 500-550°C |

| Coolant | Liquid sodium (Na) |

| Primary pressure | 0.1 MPa |

| Power Range | 50 to 1500 MWe |

| Fuel | (Pu,U) MOX or metallic fuel |

| Breeding Ratio | 0.5 - 1.3 (>1 « breeder » configuration) |

How do Sodium Fast Reactors meet Generation IV Criteria?

From the initial conception of nuclear energy, it was recognized that full realization of the energy content of uranium would require the development of fast reactors. In the current once-through fuel cycle, enriched uranium is utilized as LWR fuel and over 99% of the energy content of the initially mined uranium remains in the residue from the enrichment process and used LWR fuel. Conversely, the favorable neutron balance in a fast spectrum sustains the fissile material. This behavior improves the performance of both once-through (breed/burn and long-lived core concepts) and recycle strategies, by enabling extended fuel burnups from a fixed fissile inventory.

For closed fuel cycle applications, a thermal spectrum leads to the generation of higher actinides that complicate subsequent recycling. Conversely, fission is favored in a fast spectrum limiting higher actinide generation. This behavior allows full recycle enabling complete consumption of uranium and transuranic elements, while eliminating the need for uranium enrichment. Significant waste management benefits can also be realized by excluding the long-term heat production elements (actinides) from the waste stream.

A wide variety of actinide management strategies can be deployed in Generation-IV SFR reactors. The uranium loading can be varied to operate in different modes:

- A conversion ratio less than 1 (“transmuter” mode) which means that there is a net consumption of transuranics. Here, “transmute” means to convert transuranics into shorter-lived isotopes.

- A conversion ratio near 1 (“converter” mode) which provides a balance in transuranic production and consumption. This mode results in low reactivity loss rates with associated control benefits.

- A conversion ratio greater than 1 (“breeder” mode) which means there is a net creation of transuranics. This approach creates additional fissile materials, but requires the inclusion of extra uranium in the SFR and fuel cycle.

An appropriately designed fast reactor has flexibility to shift between these operating modes; and the desired actinide management strategy will depend on a balance of waste management and resource extension considerations.

Note: The conversion ratio is defined as the ratio of the transuranic production rate to the transuranic destruction rate, whereas, the breeding ratio is a similar ratio for the fissile material.

For the commercialization of the SFR system, it is important to achieve a level of economic competitiveness that enables system installation in accordance with market principles. For this purpose, an important goal is to achieve energy costs (unit cost of power generation) competitive with alternate future energy sources. For this purpose, the reduction of the plant capital costs is crucial. A number of innovative SFR design features have been proposed to improve SFR capital costs including:

- Configuration simplifications. These include reduced number of coolant loops by improving the individual loop power rating, improved containment design, refined (and potentially integrated) component design, and possibly elimination of the intermediate coolant loop.

- Improved Operations & Maintenance (O&M) technology. Innovative ideas are being considered for in-service inspection and repair. Remote handling and sensor technology for use under sodium are being developed, including ultra-sonic techniques. In addition, increased reliability for sodium-water steam generators (e.g., by using double tube configuration with leak detection) is being pursued by advanced detection and diagnostic techniques.

- Advanced reactor materials. The development of advanced structural materials may allow further design simplification and/or improved reliability (e.g., low thermal expansion structures and greater resistance to fatigue cracking). These new structural materials need to be qualified, and the potential for higher temperature operation evaluated.

- Advanced energy conversion systems. The use of a supercritical CO2 Brayton cycle power generating system offers the potential for surpassing 40% efficiency; a more compact design may also be possible. Cost and safety implications must be compared to conventional Rankine steam cycle balance-of-plant design.

- Fuel Handling. Techniques and components employed in previous fast reactors were reliable, but very complicated and expensive. Recent design innovations may simplify the fuel handling system, but require the development and demonstration of specialized in-vessel handling and detection equipment.

Important safety features of the Generation-IV SFR system include a long thermal response time, large margin to coolant boiling, a primary system that operates near atmospheric pressure, and an intermediate sodium system between the radioactive primary sodium and the power conversion systems. Technology development efforts focus on two general areas: assurance of passive safety response, and techniques for evaluation of bounding events. Advanced SFR designs exploit passive safety features to increase safety margins and to enhance reliability. The system behavior will vary depending on system size, design features, and fuel type. R&D for passive safety will investigate phenomena such as axial fuel expansion and radial core expansion, and design features such as self-actuated shutdown systems and passive decay heat removal systems. The ability to measure and verify the performance of these passive features must be demonstrated. Associated R&D will be required to identify bounding events for specific designs and investigate the fundamental phenomena necessary to prevent severe accident progression.

The favorable passive safety behavior of fast reactors is expected to virtually exclude the probability of severe accidents with potential for core damage. Nevertheless, design measures to mitigate the consequences of severe accidents are being considered. This approach is consistent with the defense-in-depth philosophy of providing additional safety margin beyond the design basis. A common safety approach incorporating the physical and chemical characteristics of the materials handled in the reactor (chemical activity and radio-toxicity, etc.) and unique SFR design features and phenomena should be established. The goal is to render the risk of installing SFR systems much lower than the risk of energy alternatives. Achieving this level of safety should result in licensing and regulatory simplifications that may in turn result in reduced system cost. To do this, probabilistic safety evaluations will be needed to identify design tradeoffs that assure very high levels of public health and safety.

Development of new SFR technology also provides the opportunity to design modern safeguards directly into the planning and building of new nuclear energy systems and fuel cycle facilities. Incorporating safeguards into the design phase for new facilities will facilitate nuclear inspections conducted by the International Atomic Energy Agency (IAEA). The goal of this oversight is to always have an accurate grasp of the current inventory through the utilization of advanced technologies to verify the characteristics of the security system (accountancy, detectability and promptness) and the physical protection characteristics (physical protection measures, the monitoring level and security measures) and for ensuring robust design to guarantee these characteristics. It is also necessary to maintain transparency and openness in terms of information to more effectively and efficiently monitor and verify nuclear material inventories.

Benefits and Applications of Sodium Fast Reactors

As mentioned in the “Attributes” part, the SFR has several advantages:

- Reducing the radiotoxicity and heat load which facilitates waste disposal and geologic isolation

- Enhancing utilization of uranium resources through efficient management of fissile materials and multi-recycle

- Flexibility to shift between these operating modes: “transmuter”, “converter” and “breeder”

- High power density enabling compact core designs

- Natural circulation: operation at low pressure and a large difference between inlet and outlet coolant temperatures enabling natural circulation designs which can remove decay heat from the core without relying on dynamic equipment such as pumps, especially in case of a station blackout event

- Oxygen-free environment that prevents corrosion

Main Challenges for the Deployment of SFR

The SFR system still has to solve various challenges as outlined in the "Attributes" section, yet a significant portion of these issues has been addressed and ameliorated through the long-term operation of past and existing SFR reactors.

- Sodium reacts chemically with air and water and requires a sealed coolant system.

- Sodium, which is not transparent, also requires a very different set of in-service monitoring and inspection tools and dedicated operating procedures that differ from conventional LWRs.

- Energy costs (unit cost of power generation) should be competitive with alternate future energy sources by improving SFR capital cost through the R&D of configuration simplifications, improved O&M technology, advanced reactor materials, advanced energy conversion systems and fuel handling.

- Further development of passive safety approaches and validation of their performance are key research objectives.

The work plan for the upcoming years anticipates additional research and development on safety issues underscored by the Fukushima Daiichi accident. It is expected to primarily concentrate on the following areas:

- Robust and highly reliable systems for adequate cooling of safety-relevant components and structures

- Geometric stability of the SFR core in case of a strong earthquake and assurance of reliable performance of the control rods

- Seismic-resistant design of the spent fuel pools and fuel-handling devices

- Integrity of the primary circuit and its cooling

- Design features aimed at the risk aversion of the flooding of the reactor building

- Effective options for dealing with severe accidents

How is GIF working to solve those

In it’s 2014 Technology Roadmap GIF identified the following areas of R&D as priorities for the SFR system:

- Safety and operation

- Improving core inherent safety and core instrumentation and control (I&C)

- Prevention and mitigation of sodium fires

- Prevention and mitigation of severe accidents with large energy releases

- Ultimate heat sink

- In Service Inspection and Repair (ISI&R)

- Consolidation of common safety design criteria

- Advanced fuel development

- Component design and balance of plant

- Used fuel handling schemes and technologies

- Implementation of innovative options

- Economic evaluations, operation optimisation

To know more please consult the 2014 GIF Technology Roadmap report.

GIF has established System Steering Committees (SSC) to implement research and development (R&D) cooperations for each Generation IV Reactor Concept. Each SSC is supported by the participation from GIF Members interested in contributing to collaborative R&D on the said Generation IV system. Each SSC plans and integrates R&D projects contributing to the development of a system.

The SFR SSC was established in 2006. To effectively meet GenIV system goals, the international SFR R&D activities have been arranged by the SFR Signatories into several projects, each governed by a separate Project Arrangement (PA) and managed by a Project Management Board (PMB) to organise the joint GIF research activities of the SFR system. Three projects are currently ongoing.

To learn more about the progress made by each of these joint initiatives please see the GIF annual reports and the page of the GIF SFR SSC.

SFR Projects History - Past projects

The first nuclear SFR was the EBR-I at the Idaho National Laboratory (INL) in the USA (1.4 MWth / 0.2 MWe). The EBR-I operated between 1951 and 1963. It was the first breeder nuclear reactor and also the first nuclear reactor to be used to generate electricity in the word.

With more than 20 reactors built around the world and combining nearly 400 reactor years of operation, SFRs benefit from extensive design and operating experience feedback. Experimental reactors, industrial prototypes and industrial-sized reactors were built and operated in several countries.

The following table tries to give an overview of the past, currently operating and under development reactors that use the Sodium Fast Reactor technology. Their presence in this list does not mean that the GIF considers them as fulfilling all the Generation IV Criteria. Yet it is importance to acknowledge the breadth and depth of concepts using this technology and the global knowledge and experience that has been and is still being gained through these reactors.

Project/Program | Country | Power Rating | Timeframe | Notes |

|---|---|---|---|---|

| EBR-1 | Idaho National Laboratory, US | 1.4 MWth 200 kWe | 1950 - 1964 | First SFR operation, first breeder reactor. |

| Sodium Reactor Experiment | Atomics International, US | 20MWth 6.5 MWe | 1957 - 1964 | |

| BR-5/BR-10 | Soviet Union then Russian Federation | 5 MWth/10MWth | 1959 – 1964 (PuO2 fuel) 1964-1972 (Uranium carbide core) (PuO2 at 10MWth: BR10) | BR-5 was the first reactor in the world to be operated with plutonium oxide fuel |

| Dounreay Fast Reactor (DFR) | United Kingdom | 60 MWth | 1959 – 1977 | Experimental reactor |

| Fermi 1 | DTE Energy Electric Company, US | 430 MWth 150 MWe | 1963 - 1975 | Suffered partial meltdown |

| EBR-2 | Argonne National Laboratory, US | 62.5 MWth 20 MWe | 1965 - 1994 | Pool-type, 67% w/o enriched U-235 |

| Rapsodie | France | 40 MWth | 1967 - 1983 | Loop-type, prototype |

| BOR-60 | RIAR, Dimitrovgrad, Soviet Union then Russian Federation | 60 MWth 12 MWe (from 1973) | 1969 - 2017 | Low-power reactor focused on the development and irradiation of fuel and structural materials for sodium-cooled fast reactor systems. |

| SEFOR | USA | 20 MWth | 1969 - 1972 | Experimental breeder |

| BN-350 | Shevchenko /Aktau, Soviet Union (current Kazakhstan) | 592 MWth 150 MWe | 1972 – 1994/1999 | Used to power a water desalination plant (120 000 m3/day) making the total output equivalent to 350MWe |

| KNK-II | Germany | 58 MWth 17 MWe | 1974 - 1991 | Testing facility for fuel elements |

| Prototype Fast Reactor (PFR) | United Kingdom | N/A | 1974 - 1994 | Fueled with MOX |

| Phénix | CEA(1), EDF(2), France | 22 MWth 9 MWe | 1973 - 2010 | 264MWth, Breeding ratio 1.16 |

| SNR-300 | Germany | 327 MWth | 1985 - 1991 | Never critical |

| Fast Flux Test Facility | DOE(3), US | 400 MWth | 1978 - 1993 | Not for electricity generation |

| Superphénix | EDF, Enel(4), France | 3000 MWth 1242 MWe | 1986 - 1997 | Largest SFR |

| Monju | Japan Atomic Energy Agency, Japan | 714 MWth 280 MWe | 1995/2010 | Loop type. Operation was suspended for 15 years. Briefly restarted in 2010. |

(1) Commissariat à l'énergie atomique et aux énergies alternatives, (2) Électricité de France S.A. , (3) U.S. Department of Energy, (4) Ente Nazionale per l'Energia eLettrica

SFR Current Developments

Operating SFRs

Several SFRs are currently operating in the world.

| Project Name | Country | Power Rating | Expected Deployment Date | Notes |

|---|---|---|---|---|

| Joyo | Japan Atomic Energy Agency, Japan | 140-150 MWth | 1971 - Present | Went through 3 core changes: MK-1, MK-2, MK-3, with increasing power |

| BN-600 | Soviet Union, Russia | 560 MWe | 1980 - Present | |

| FBTR | IGCAR(5), BARC(6), India | 40 MWth 13.2 MWe | 1985 - Present | Reached 40MWth in 2022 |

| CEFR | China Institute of Atomic Energy, China | 65 MWth 20 MWe

| 2012 - Present | 65MWth, built by Russia |

| BN-800 | Russia | 2100 MWth 789 MWe | 2015 - Present | |

| CFR-600 | China National Nuclear Corporation, China | 1500 MWth 600 MWe | 2023 - Present | Xiapu-1, Xiapu-2. FBR |

| PFBR | India | 1253 MWth 500 MWe | 2024 - Present | U-Pu Fuel Cycle |

(5) Indira Gandhi Center for Atomic Research (6) Bhabha Atomic Research Centre

SFRs under development

| Project/Program | Country | Power Rating | Expected Deployment Date | Notes |

|---|---|---|---|---|

| BN-1200 | Russia | 2900 MWth 1220 MWe | Not yet constructed | Based on BN-600 and BN-800 |

| ASTRID | France | 600 MWe | Cancelled, project development lasted from 2012 to 2019. | Expected to be a prototype of Gen IV SFRs Project cancelled in 2019 |

| Natrium | TerraPower, US | 840 MWth / 345 MWe | Licensing | SMR design |

| 4S | Toshiba, Japan | Two configurations: 30 MWth, 135 MWth | Pre-Licensing | |

| ARC-100 | ARC Clean Technology, US/Canada | 286 MWth | Pre-Licensing | Sodium-cooled fast reactor using metallic uranium alloy fuel with a 20-year refueling cycle. |

| HEXANA | Hexana, France | 2*400MWth | SFR, intended to have two modules deployed per plant and coupled with a molten salts thermal storage system. Will build upon French CEA gained experience in the SFR technology. | |

| Otrera 300 | Otrera Nuclear Energy, France | 300 MWth | SFR for cogeneration and low-level heat (<150°C) with the possibility to be used for minor actinides burning. |

GIF SFR Related Publications

GIF has produced several reports and conducted analysis on SFR Systems produced by cross cutting methodological working groups (Risk and Safety WG, Proliferation Resistance & Physical Protection Working Group). GIF's annual reports, technology roadmap and R&D Outlooks provide more information on the progress made by GIF's GFR System Steering Committee and Project Management Boards.

GIF SFR Related Presentations

Members of the GIF have delivered numerous presentations highlighting the advancements in SFR Technologies and related R&D as well as GIF efforts in this area, some of which are listed here.

GIF SFR Related Webinars

References

Caciuffo, Roberto & Fazio, C. & Guet, Claude. (2020). Generation-IV nuclear reactor systems. EPJ Web of Conferences. 246. 00011. 10.1051/epjconf/202024600011.

Hiroyuki Ohshima, Shigenobu Kubo, Chapter 5 - Sodium-cooled Fast Reactors (SFRs), Editor(s): Igor L. Pioro, In Woodhead Publishing Series in Energy, Handbook of Generation IV Nuclear Reactors (Second Edition), Woodhead Publishing, 2023, Pages 173-194, ISBN 9780128205884, https://doi.org/10.1016/B978-0-12-820588-4.00006-2.

Baque F., K. Paumel, G. Cornloup, M.A. Ploix and J.M. Augem, Non-destructive Examination of Immersed Structures within Liquid Sodium, ANIMMA 2011, Ghent, June 6-9 (2011).

International Atomic Energy Agency Advanced Reactors Information System (ARIS) Online Database

Joo Y.S., C.G. Park, J.B. Kim and S.H. Lim, Development of Ultrasonic Waveguide Sensor for Under-sodium Inspection in a Sodium-cooled Fast Reactor, NDT&E International 44, pp.239-246 (2011).

Floyd J., N. Alpy, D. Haubensack, G. Avakian and G. Rodriguez, On-design Efficiency Reference Charts for the Supercritical CO2 Brayton Cycle coupled to a SFR Proc. ICAPP2011, Nice, France, 2-5 May 2011, Paper 11054.

Moisseytsev A. and J.J. Sienicki, Dynamic Simulation and Control of the S-CO2 Cycle: From Full Power to Decay Heat Removal Proc. ATH 12, Embedded Topical Meeting of ANS 2012 Winter Meeting, San Diego, CA, USA, 11-15 November 2012, Paper 6461.

Sienicki J. J. et. al., Synthesis of Results Obtained on Sodium Components and Technology Through the Generation IV International Forum SFR Component Design and Balance-of-Plant Project, Proc. FR13, Paris, France, 4-7, March 2013.

Delage F. et. al., Status of advanced fuel candidates for Sodium Fast Reactor within the Generation IV International Forum, J. of Nuclear Materials, NUMA46668, 2013.

News related to the SFR System

June 2024 Terra Power breaks ground for Natrium Plant - https://www.world-nuclear-news.org/Articles/TerraPower-breaks-ground-for-Natrium-plant

Oct 2023 Three microreactor designs selected for US test bed experiments - https://www.world-nuclear-news.org/Articles/Three-microreactor-designs-selected-for-US-test-be,

October 2022, Defueling completed at Japan's Monju reactor - https://www.world-nuclear-news.org/Articles/Defuelling-completed-at-Japan-s-Monju-reactor –

May 2022 First tests under way at new US liquid metal facility - https://www.world-nuclear-news.org/Articles/First-tests-under-way-at-new-US-liquid-metal-facil ,

January 2022 US, Japanese firms agree to cooperate on fast reactors - https://www.world-nuclear-news.org/Articles/US,-Japanese-firms-agree-to-cooperate-on-fast-reac ,

January 2013, Sodium coolant arrives at fast reactor - https://www.world-nuclear-news.org/Articles/Sodium-coolant-arrives-at-fast-reactor